Edge Grain vs End Grain Cutting Boards: A Simple Guide

Cutting boards are a staple in almost every kitchen and are quite commonly used. However, not all cutting boards are created equal.

When it comes to choosing between end grain and edge grain boards, the decision goes beyond aesthetics. Both types of cutting boards possess qualities that can affect your knives, time spent maintaining the board, and have different uses in the kitchen. They are both also built in different ways and require a different set of skills and tools to build them.

In this article, I will take a deep dive into the differences between these two main types of cutting boards: end grain boards and edge grain boards.

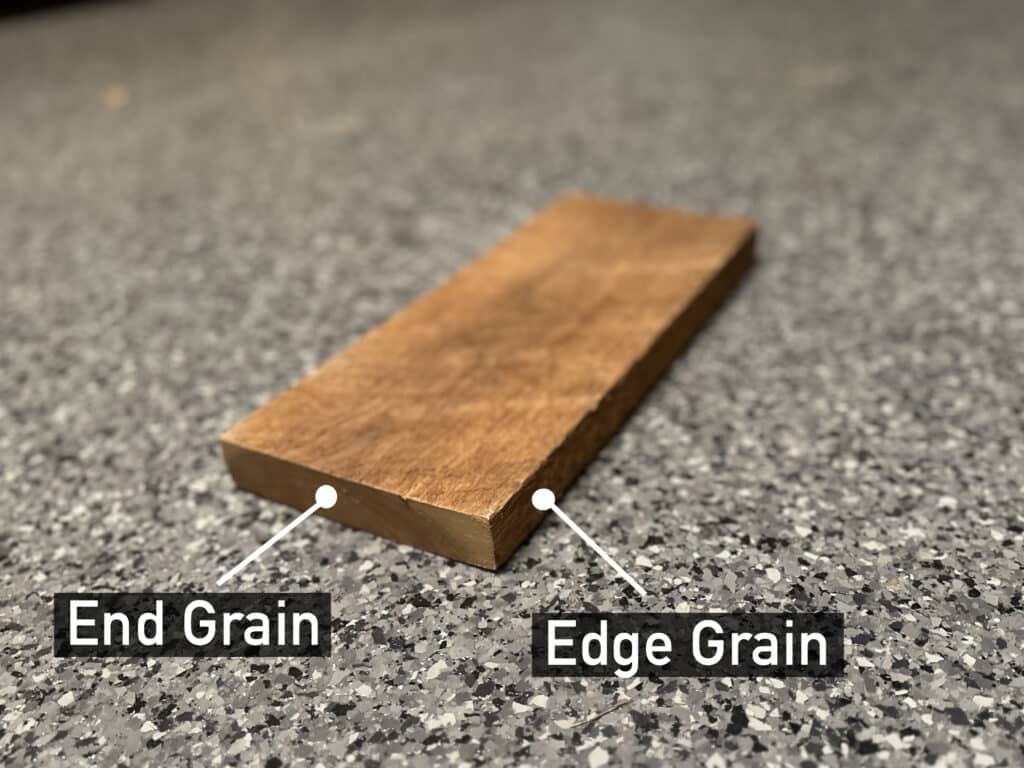

End Grain vs. Edge Grain: The Main Difference

Let’s start by discussing the main differences between these two types of boards. The main difference between these two types is how the piece of lumber is cut and assembled in order to make the cutting board.

Edge grain boards have grains that run horizontally along the face of the board. On the other hand, end grain cutting boards have grain that runs vertically, so the grain ends on the cutting surface and the underside of the board.

Edge Grain Cutting Boards

An edge grain cutting board is a type of wooden board that is made by arranging flat strips of wood to make the cutting surface.

These strips of wood are typically made by running larger pieces of wood through a table saw in order to create smaller strips of wood. This is called ripping the boards.

The strips of wood are then glued together, which creates a beautiful and dense surface for preparing and serving food. This shows off the beautiful long grain of the long strips of wood.

These types of boards are not only practical and durable, but they make a beautiful decorative piece for your kitchen.

Below is an example of an edge grain cutting board. The wood type I made this out of is walnut wood, hard maple, mesquite, and purple heart. Acacia is another great choice of wood for a cutting board.

This particular board was made large (18 inches by 32 inches) in order to house large briskets that were smoked on a Traeger. A juice groove was added to help keep things clean. Additionally, I added feet to the bottom in order to protect whatever countertop the board would sit on. I added finger grooves to the side so that the board can easily be picked up.

As you can see, the wood grain runs along the surface of the board, making it an edge grain board.

Pros of Edge Grain Cutting Boards

One huge benefit of edge grain cutting boards is affordability. Edge grain cutting boards are slightly easier to assemble and use less wood than end grain cutting boards. So, this helps keep the cost down. Overall, edge grain cutting boards are more affordable than end grain cutting boards.

Additionally, there is less maintenance needed for an edge grain board when compared to an end grain board. Being that the grain goes along the length of the board, it absorbs less oil and therefore, needs to be oiled less often.

Of course, all cutting boards require some maintenance and proper care. However, an edge grain board requires less maintenance than an end grain board.

It’s always a good idea to seal your board with a high-quality sealer. Although mineral oil is a go-to for many people, my personal preference is Odie’s Oil. I have made many, many cutting boards and this is always my go-to sealer for cutting boards. It smells wonderful, effectively seals the boards, and is food-safe.

Cons of Edge Grain Cutting Boards

Edge grain cutting boards can be more prone to warping or cracking than end grain boards. This is especially true along the edges. Cutting boards should be thoroughly cleaned and dried to help prevent warping or cracking.

Effectively caring for your board will greatly help reduce cracking or splitting, however, edge grain boards are more likely to crack than end grain boards.

Because of how the grain of the wood runs, an edge grain cutting board will show a cut mark much more readily than an edge grain cutting board. These knife marks can be sanded out and re-sealed, however. If you want to display your board and the knife marks bother you, an end grain board might be a better option.

Edge grain boards will also wear your kitchen knives down much faster than an end grain board will. The surface is more dense and the wood fibers don’t spread apart like an end grain board. So, you will have more maintenance on your knives as well.

End Grain Cutting Boards

An end-grain board is assembled in a way that has the ends of the boards facing up and down. The grain flows vertically. Because every board is different, every end grain cutting board has its own unique and beautiful design. They show off the wood piece’s beautiful growth rings and are displayed on the surface of the board typically in a checkerboard pattern.

End grain wooden cutting boards are not just beautiful and unique, they would work wonderfully in a kitchen where there is heavy chopping done and the board is used quite often. It would also work best in a kitchen where the board is kept out on the countertop, as it can be heavy and cumbersome to move.

Pros of End Grain Cutting Boards

End grain boards show fewer knife marks than edge grain boards. This is because the knife blade goes between the fibers of the wood, which can then close back up. So, the surface of the wood is less damaged by the knife edge.

Because of this, end grain cutting boards are the most durable of the two types of boards being compared in this article. An end grain butcher block are a popular choice because they can withstand heavy use.

Cons of End Grain Cutting Boards

Applying oil is needed more often for this type of board. This is because the pores readily soak up any kind of oil or sealer that is added to the board. So, you will need to oil your end grain board on a regular basis. Doing so will help to avoid cracking and splitting and will keep the board looking beautiful.

End grain boards typically cost more than edge grain or face grain boards. This is because they are harder to build and require more wood to make them.

Although edge grain boards can be heavy, end grain boards are typically heavier overall. They are more likely to be much thicker than an edge grain board. The thickness helps to prevent cracking. So, this type of wooden cutting board can be cumbersome to move around or to find a place to store it. This is an important factor to consider when you are planning where to store the board in your kitchen.

One last con of an end grain cutting board that I would like to cover is the extra skillset and tools needed to make one. End grain cutting boards should not be run through a planer like an edge grain cutting board can be. The probability of chip out resulting in injury is likely when an end grain board is run through a planer.

Because of this, a large drum sander is needed. These aren’t typically available in everyday shops. So, end grain boards are slightly harder to build.

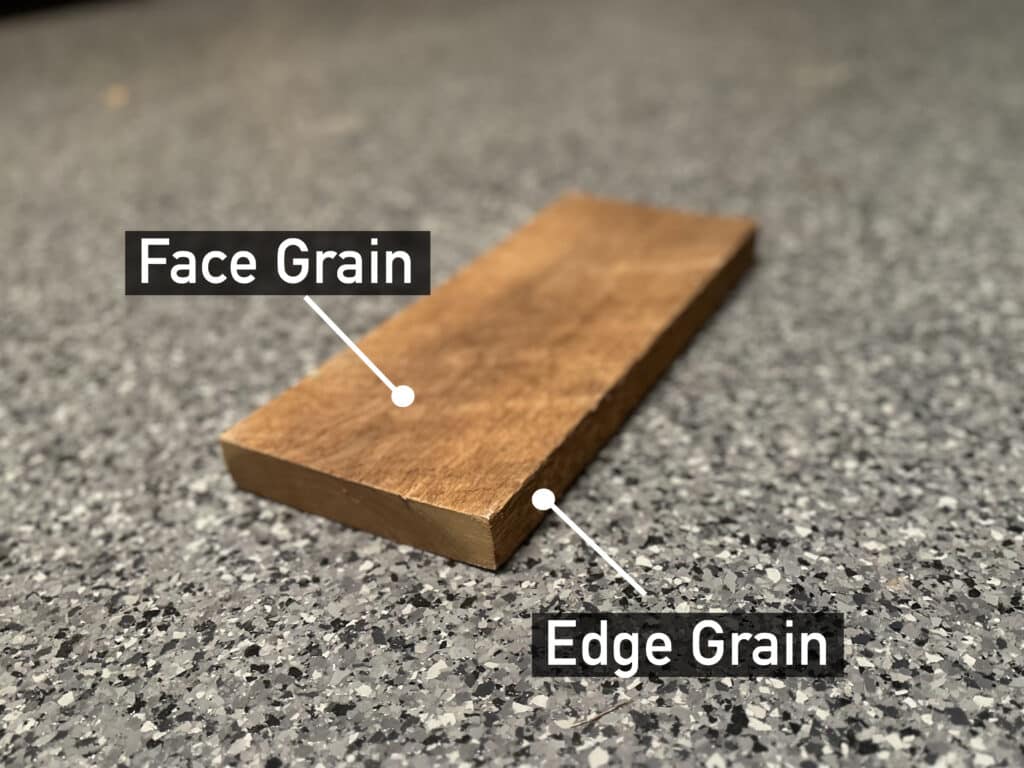

Face Grain Cutting Board

I would also like to mention a third type of board: a face grain cutting board. This is very similar in looks to an edge grain cutting board. However, the difference is that the material perpendicular to the edge grain is used. It can be very hard to spot the difference between the two once the board is assembled.

In fact, a face grain cutting board and an edge grain cutting board will have the same wear and tear on your knives, are made essentially the same way, look almost identical, and require the same maintenance.

Due to the similarities, I lumped this in with category of edge-grain cutting boards, although it is technically different.

What Type of Board is Best?

You will need to assess the needs in your kitchen to decide which type of board is the best choice for you.

If you have a higher budget, will be doing excessive chopping, and are okay with somewhat regular maintenance, an end grain board would be a great option.

If you are limited on your budget, are ok with knife marks, and will use the board for a moderate amount of food preparation, an edge grain board would be a great choice.

Hopefully reading through the differences between an end grain and edge grain board will aid you in making an informed decision on which board is the best option.

Related Topics

If you found this article helpful, be sure to check out the following articles:

Suzie Wible

Suzie has shared her knowledge for over 10 years about building furniture, painting techniques, how to build your dream home, and basic to advanced woodworking skills. Through this blog, readers will feel empowered to create a home and products they love too.