How Long It Takes for Concrete to Set

Being that we just completed the concrete slab foundation for our new construction home, I thought it would be a great time to tackle the question of how long it takes for concrete to set.

There are a few specific details concerning the curing process for this particular project that come into play when answering this question. I will cover all of them as they pertain to our situation. This will further guide you in figuring out drying times for cement project.

Type of Concrete Project

The dry times I will give you are for a concrete slab foundation for a new home construction. The home will be around 3,200 square feet. The foundation is around 10″ thick. There are different concrete mixes for different projects, and this particular article will cover a new home slab.

Outside Temperature When Pouring Concrete

The temperature outside when this concrete was poured was very hot. It was poured in July when the weather conditions were not particularly ideal for pouring fresh concrete. Because of this, the concrete company arrived at the project site around 5:00 am to begin work. This way, they could complete the bulk of the work before it got too hot outside.

The temperature at the time they began was around 75 degrees fahrenheit. The temperature outside gradually rose to just under 100 degrees fahrenheit by 2:00pm that afternoon.

Both of these factors (type of project and weather conditions) will greatly affect the drying process and the concrete drying time for your particular project.

How Long Does it Take for Concrete to Set

The crew finished pouring around 11:00 am. The concrete could handle foot traffic about 5 hours later. Framing for the home started 3 days after that. So, you can start building on the concrete slab around day 5 after the pour. Allow around 25 days for the concrete to reach full strength if you will be driving on the concrete.

While you’re in the framing stage, it would be a great time to write bible verses on the studs of your new home construction.

The Process to Pour a Concrete Foundation for a New Construction Home

Before the new concrete slab can be poured, there are quite a few things that need to be completed.

The first step is to clear the lot. Our lot was heavily wooded. Although we saved every tree we could, we had to remove a few large trees on our home site in order to build.

This had to be done with heavy machinery (not just chainsaw work by cutting down the tree at the base), This is because the roots have to be completely removed. If they aren’t completely removed, they can cause foundation issues down the road, as roots take awhile to fully die and can cause the foundation to shift.

The second step is to set the forms for the concrete. The crew used a combination of the lot survey and wood forms to outline the slab foundation.

Once the forms were set, plumbing, gas, and electricity lines were added. It was very important to get this steps correct because once the concrete is poured, it is very difficult to move anything. Concrete would have to be crushed and removed, the lines moved, then concrete poured again. It is important to inspect this step closely.

Speaking of new construction homes, you can find a free checklist for new home construction steps in this post.

The forms were now bagged with a black plastic material that helps keep everything in place and where it needs to stay. Then, steel was added over the bags for reinforcement when the concrete was poured.

Once these items are completed, the concrete can now be poured.

Pouring the Concrete

Now that the above steps are complete, the concrete slab foundation can be poured.

Most likely, a cement truck with a pump arm will do the pouring. The whole process took around 5 hours to complete. The square footage for this project is around 3,200 to give you an idea.

The drops that you see below are for showers.

There were multiple groups of people working while the concrete was being poured. One group was actively pouring the wet concrete into the forms. Another was using a concrete screed for the finishing part of the pour. This was after the concrete had dried for around 1 hour and was still somewhat wet.

Lines from the screed are smoothed out during the hours after the pours as well. The dry concrete surface will be a smooth finished product.

Once the concrete cures fully, the forms and molds can be removed.

Keep the Concrete Moist

It is important to note that because the concrete was poured during such a hot time, it was imperative to keep the concrete wet as much as possible for the first week or so after the pour. This is the best way to keep the concrete temperature down and achieve the best results.

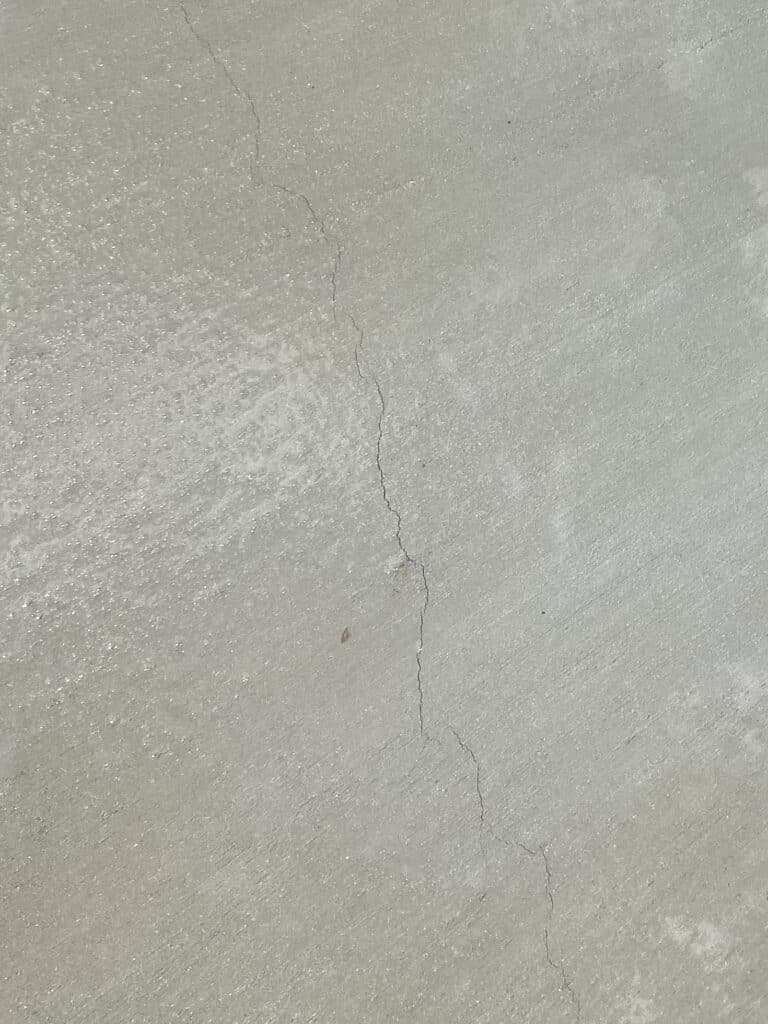

You will want to keep as much moisture from quickly evaporating from the concrete pour as possible, so the chemical reaction has time to process and reach maximum strength. This is less important if the concrete is poured during cold weather or freezing temperatures. If the moisture content goes down too quickly, small cracks can occur, as seen below.

About 4 hours after the concrete was poured, we set up multiple sprinklers that kept constant water on the newly poured concrete. We did this for the whole first day.

After that, we had the sprinklers spraying water for about 4 hours a day during the hottest part of the day. We still had small hairline cracks because the curing time was so quick. How much water is needed for your project will be determined by the project, type of concrete, and temperature outside.

For a different concrete project, check out this wood and concrete table!

The company we worked with kept saying that the more water after the pour, the better. Thi was especially true with the heat we were working with. The amount of water needed for the correct concrete cure times will depend on the weather forecast as well. So in this case, rain would have been great. Slowing the concrete setting time down as much as possible is best for concrete that is curing.

If, once your concrete is poured and cured, you have any rust stains, check out this post on how to remove rust stains from concrete. This happened to use during the framing stage. The framers left nails on our freshly poured slab, which got rained on, which caused rust spots on our porch. In that post, I outline the steps to removing rust stains left on the concrete.

Driveway and Walkway Concrete Pours

Things like driveways and walkways are poured as one of the last steps in construction. This is because there are so many trucks and heavy equipment constantly coming and going on the work site, that they could damage the poured concrete. The overall strength hasn’t been reached because the hardening process hasn’t been completed.

The trucks could even cause cracks under the surface that you can’t see right away. However, they will cause concrete cracking issues later down the road. So, save the concrete pours for the driveway for the end of the project in order to protect the concrete.

It is important to note that these are our numbers for our particular project. Be sure to talk to your sub-contractors who are trained and skilled in pouring new concrete slabs, as they will give you further guidance on how long concrete takes to set. Air temperature, the amount of moisture in the concrete, and dry weather vs wet weather are all things to take into consideration.

Suzie Wible

Suzie has shared her knowledge for over 10 years about building furniture, painting techniques, how to build your dream home, and basic to advanced woodworking skills. Through this blog, readers will feel empowered to create a home and products they love too.